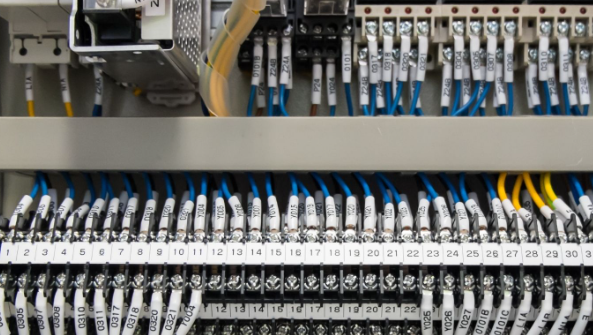

Role of PLC in Smart Factories and Industrial Digitalization

In modern manufacturing, automation and digital transformation are reshaping how industries operate. Programmable Logic Controllers (PLCs) play a crucial role in smart factories by enabling real-time control, monitoring, and data integration. Advanced industrial components such as 150-c25nbd contribute to improving system reliability and automation efficiency in digital production environments.

Introduction to PLC in Smart Factories

Smart factories rely on connected devices, intelligent control systems, and data-driven decision-making. PLC systems act as the backbone of industrial automation by controlling machines, processes, and equipment with high precision.

What is a PLC in Industrial Automation?

A PLC is an industrial computer designed to control manufacturing processes and machinery. It receives input signals from sensors and switches, processes programmed logic, and sends output commands to actuators and devices.

Key functions include:

- Real-time process control

- Machine automation

- Data collection and monitoring

- Communication with SCADA and MES systems

Components like 150-c25nbd enhance automation systems by supporting stable performance and seamless integration within control architectures.

Importance of PLC in Industrial Digitalization

Industrial digitalization involves integrating automation systems with cloud platforms, IoT devices, and advanced analytics. PLC systems are essential for connecting physical operations to digital platforms.

Data Collection and Connectivity

Modern PLCs collect operational data from machines and sensors. This data is transmitted to cloud systems or control servers for analysis.

Benefits include:

- Real-time production monitoring

- Predictive maintenance

- Improved efficiency

- Reduced downtime

Industrial modules such as 150-c25nbd support reliable communication and control functions, helping factories maintain stable digital operations.

Integration with IoT and Smart Systems

Smart factories connect PLCs with IoT devices to enable smart monitoring and automation.

Key integration features:

- Ethernet-based communication

- Remote diagnostics

- Cloud connectivity

- Automated reporting

Using advanced control modules like 150-c25nbd, manufacturers can build scalable automation systems that support Industry 4.0 standards.

Key Benefits of PLC in Smart Manufacturing

PLC systems provide multiple advantages in digital production environments.

Improved Operational Efficiency

PLCs optimize machine performance by reducing manual intervention and human errors. Automated control ensures consistent production quality.

Advantages include:

- Faster processing speed

- Accurate control logic

- Reduced waste

- Better resource utilization

Reliable industrial components such as 150-c25nbd enhance system stability in demanding factory environments.

Enhanced Safety and Monitoring

Safety is critical in smart factories. PLCs monitor equipment conditions and trigger alarms when abnormal situations occur.

Safety improvements include:

- Emergency shutdown control

- Fault detection

- Equipment monitoring

- Real-time alerts

The integration of control modules like 150-c25nbd ensures continuous supervision of industrial processes.

Future of PLC in Digital Industrial Transformation

As factories become more automated, PLC technology continues to evolve with advanced features.

AI Integration and Advanced Analytics

Future PLC systems will integrate artificial intelligence and machine learning to improve decision-making.

Potential improvements:

- Predictive maintenance algorithms

- Automated performance optimization

- Intelligent process control

- Smart fault detection

Industrial automation solutions built around components like 150-c25nbd will support scalable digital infrastructure.

Conclusion

PLC systems are the foundation of smart factories and industrial digitalization. They enable real-time control, data communication, and intelligent automation. Modern industrial modules such as 150-c25nbd contribute to system reliability and efficient integration in advanced manufacturing environments.

As digital transformation expands, PLC technology will remain essential for improving productivity, safety, and connectivity in smart industrial operations.

FAQs

1. Why are PLCs important in smart factories?

PLCs control machines, collect data, and enable real-time communication between industrial devices, making them essential for automation and digital integration.

2. How does 150-c25nbd support industrial automation?

The 150-c25nbd component enhances control system stability and communication reliability, supporting efficient automation in digital factory environments.

3. What is the future role of PLC in industrial digitalization?

Future PLC systems will integrate with AI, cloud computing, and IoT technologies to enable predictive maintenance, smart monitoring, and advanced process optimization.